| |

|

Jute, kenaf, and other allied fibers (JAF) are the second most important natural

fibers next to cotton. Kenaf is a bast fiber crop that has been used for a long time as cordage, ropes,

etc. Kenaf, Species: Hibiscus cannabinus, L.Family: Malvaceae , is a warm-season annual fiber crop related to cotton, okra, and hibiscus. The plants, which reach heights

of 8 to 20 feet, are harvested for their stalks from which the fiber is

extracted. Its coomon names are: English: kenaf , India (Bengal): mesta,

Chennai: palungi, Bombay: deccan hemp, Andhra Pradesh: Bimli jute, Taiwan: ambari,

Egypt & northern Africa: til, teel, or teal. Indonesia: Java jute,

Brazil: papoula de Sao Francisco, South Africa: stokroos and West Africa: dah, gambo, and rama. Grown for thousands of years in Africa where its leaves are consumed in human

and animal diets, the bast fiber used for cordage, and the woody core of the

stalks burned for fuel; this crop was introduced into southern Asia around 1900.

Principal production areas are China, India, and the Tashkent.

|

Kenaf agriculture |

Kenaf Plant |

Kenaf Plant:

Kenaf is a short-day, annual herbaceous plant cultivated for the soft bast fiber in its stem.

Kenaf is closely related to cotton, okra, and the hollyhocks. Kenaf

grows quickly, rising to heights of 12-14 feet in as little as 4 to 5

months. While the flowering can last 3 to 4 weeks, or more, per plant,

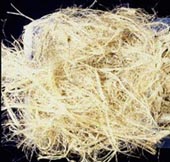

each individual flower blooms for only one day. The kenaf stalk contains two distinct fibers, i.e., long, jute-like bast fibers

in its bark and the short, balsawood-like core fibers. The bast fibers have been

used traditionally in the manufacture and trade of cordage products such as

burlap cloth, twine, and ropes. General Felt Industries, a major importer of

jute/kenaf fibers, had followed the kenaf work since the late 1970s.The kenaf stalk contains two distinct fibers, i.e., long, jute-like bast fibers

in its bark and the short, balsawood like core fibers. The bast fibers have been

used traditionally in the manufacture and trade of cordage products such as burlap cloth, twine, and ropes.

The outer fiber is called "bast" and comprises roughly

40% of the stalk's dry weight. The refined bast fibers measure 2.6mm

and are similar to the best softwood fibers used to make paper. The

whiter, inner fiber is called "core", and comprises 60% of

the stalk's dry weight. These refined fibers measure .6mm and are

comparable to hardwood tree fibers, which are used in a widening range

of paper products. Upon harvest, the whole kenaf plant is processed in

a mechanical fiber separator, similar to a cotton gin. The separation

of the two fibers allows for independent processing and provides raw

materials for a growing number of products including paper, particle

board, animal bedding and bioremediation aids. Kenaf plants grows quickly and can

attain a height of 12 to 14 feet in a growing season (4-5 months).

Kenaf can produce 5-10 tons of dry fiber per acre. The plant has two types of fiber--the outer, bast fibers (about 1/3 of the plant) and the inner, core fibers (about 2/3 of the plant). Generally, these two parts have separate applications.

|

|

At

the end of the growing season, the kenaf plant flowers. After blooming

the flower drops off, leaving a seed pod behind. The flowers are

yellow or white, usually with red centres, and are very short-lived.

The fruits, when formed, are fleshy. African origin kenaf plant they

require an additional 60-90 days of frost free conditions to reach the

point of germination. For production of good quality fibres, the crop

is harvested soon after the commencement of flowering, but if the

produce is intended for pulping, plants are allowed to remain until

growth ceases or is stopped by frost. Grown for thousands of years in Africa where its leaves are consumed in human

and animal diets, the bast fiber used for cordage, and the woody core of the

stalks burned for fuel.

|

Kenaf Flower |

Kenaf Leaves

Kenaf Fibers

|

The kenaf plant is considered one of the most promising alternatives to virgin soft and hard woods for paper production.

The USDA identified kenaf as the best non-wood paper alternative for several reasons:

1. Rapid growth: Kenaf reaches 12-18 feet in 150 days, while southern pine (A species commonly grown on tree plantations) must grow 14 to 17 years before it can be harvested.

2. High yield: Kenaf also yields more fiber per acre than southern pine producing 5-10 tons of dry fiber per acre, or approximately 3 to 5 times as much as southern pine.

3. Exceptional papermaking characteristics: Less chemicals, heat and time are required to pulp kenaf fibers because they are not as tough as

wood pulp and contain less lignin (an average kenaf plant contains only 9% lignin, while southern pine contains 29% lignin). Lignin is a resin that binds the cellulose fibers in plants or trees together. Toxic chemicals such as chlorine are predominantly used to delignify and bleach wood pulp. Kenaf can be quickly and easily pulped and bleached with harmless chemicals, such as hydrogen peroxide.

Despite its commercial and environmental advantages, the kenaf paper industry is as yet undeveloped.

Due to significant industry start up costs, smaller economies of scale and government subsidies to the pulp, paper and timber industries, kenaf paper is more expensive than virgin wood-based papers.

Kenaf, like many virgin wood fibers, is presently pulped by the kraft process. Pulping is a polluting process. However, kenaf pulping requires less chemical inputs and consumes less energy than most virgin wood pulping processes and is thus less polluting.

|

|

Kenaf hybrid varieties KB2 and KB11 developed by Institute of Bast

Fiber Crops, China, yield 3.7 ton/ha fibers, which is about 16% higher than

control variety. Under IJO project, scientists in Biotechnological Research

Center, Chinese Academy of Agricultural Sciences, have successfully produced the

first trasgenic kenaf plant by transforming the fungal resistance genes

Chitinase and glucanase into kenaf. Total kenaf production in 99/00 was 0.51 million tons, among which

production from China accounts for 44%, India for 39%, Thailand for 12%, and the

remaining are from Indonesia, Vietnam and other countries.

KENAF COMMERCIALIZATION ACTIVITIES

Kenaf International initiated its seed increase operations in 1981,

only in 1990 did its management decide that it was appropriate to commence

commercial seed sales. Sales in 1991 are expected to show an increase over 1990

and projections call for steady but not spectacular growth in seed sales through

the next few years or until a commercial project begins using kenaf on a

significant scale. Sales to date are primarily domestic, but a significant

portion is entering the international market. Kenaf International is dedicated

to maintaining a commercial scale inventory of viable seed for the principal kenaf cultivars in a manner that will keep the cost of seed reasonable for

farmers. A successful efforts of Natural Fibers of Louisiana, Inc. to start up the first commercial kenaf fiber separation facility

in the United States is to be mentioned here.

|

|

|