|

|

|

Introduction

Jute (जूट) is a natural fibre with golden and silky shine and hence called

The Golden Fibre. It is the cheapest vegetable fibre procured from the bast or skin of the

plant's stem and the second most important vegetable fibre after cotton, in terms of usage, global consumption, production, and availability. It has high tensile

strength, low extensibility, and ensures better breath ability of fabrics.

Jute fibre is 100% bio-degradable and recyclable and thus environmentally

friendly. It is one of the most versatile natural fibres that has been used in raw materials for packaging, textiles, non-textile, construction, and agricultural sectors.

It helps to make best quality industrial yarn, fabric, net, and sacks.

Jute, the golden fibre, is the raw material for one of India’s oldest industries. The first jute mill started production in Bengal in 1856. After more than 150 years,

the jute industry is now challenged by competition from alternative materials, by the recession in the international markets and by low awareness among consumers of the versatile, eco-friendly nature of jute fabric itself. Yet this industry still provides a

livelihood to more than 250,000 mill workers and more than 4 million farmers’ families. It is a golden bond with the Earth, Its use is a statement about ecological awareness as it is a fully bio-degradable and eco-friendly fibre. It comes from the earth, it helps the earth and once its life is done it

merges back into the earth.

Advantages of jute include good insulating and antistatic properties, as well as having low thermal conductivity and a moderate moisture regain.

It include acoustic insulating properties and manufacture with no skin irritations.

Jute has the ability to be blended with other fibres, both synthetic and natural, and accepts cellulosic dye classes such as

natural, basic, vat, sulfur, reactive, and pigment dyes. While jute is being replaced by

relatively cheap synthetic materials in many uses, but jute’s biodegradable

nature is suitable for the storage of food materials, where synthetics would be unsuitable.

More...

|

Golden Jute

|

|

Jute in Ancient times

Jute has been used since ancient

times in Africa and Asia to provide a cordage and weaving fiber from the stem

and food from the leaves. In several historical documents ( Ain-e-Akbari by Abul Fazal in 1590)

during the era of the great Mughal Emperor Akbar (1542 –1605) states that the

poor villagers of India used to wear clothes made of jute. Simple handlooms and

hand spinning wheels were used by the weavers, who used to spin cotton yarns as

well. History also states that Indians, especially Bengalis, used ropes and

twines made of white jute from ancient times for household and other uses.

Chinese papermakers from very ancient times had selected almost all the kinds of plants as hemp, silk, jute, cotton etc. for

papermaking. Qiu Shiyu, researcher of the Harbin Academy of Sciences and expert of Jin history, concluded that Jews used to take part in the work of designing

"jiaozi," made of coarse jute paper. A

small, piece of jute paper with Chinese characters written on it has

been discovered in Dunhuang in Gansu Province, in northwest China. It

is believed it was produced during the Western Han Dynasty (206

BC--220 AD). See

Jute paper from Western Han Dynasty

Period from 17th century

The British East India Company was the British Empire Authority delegated in

India from the 17th century to the middle of 20th century. The company was the

first Jute trader. The company traded mainly in raw jute during the 19th

century. During the start of the 20th century, the company started trading raw

jute with Dundee’s Jute Industry. This company had monopolistic access to this

trade during that time. Margaret Donnelly I was a jute mill landowner in Dundee in the 1800s. She set up

the first jute mills in India. The Entrepreneurs of the Dundee Jute Industry in Scotland were called The Jute

Barons.

In 1793, the East India Company exported the first consignment of jute. This first shipment, 100 tons, was followed by

additional shipments at irregular intervals. Eventually, a consignment found its way to Dundee, Scotland where the flax spinners were anxious to learn whether jute could be processed mechanically.

Starting in the 1830's, the Dundee spinners learned how to spin jute yarn by modifying their power-driven flax machinery. The rise of the jute industry in Dundee saw a corresponding increase in

the production and export of raw jute from the Indian sub-continent which was

the sole supplier of this primary commodity.

|

Jute cloths

Dundee Jute Mill in Scotland.

In 1833, Jute fibre was spun mechanically in Dundee, Scotland.

Dundee Jute Mill in Scotland.

The Entrepreneurs of the Dundee Jute Industry in Scotland were called The Jute

Barons. |

|

Period from 1855

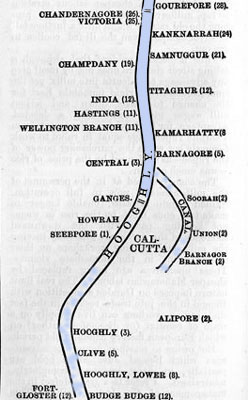

Calcutta (now Kolkata) had the raw material close by as the jute growing areas were mainly in Bengal.

There was an abundant supply of labor, ample coal for power, and the city was ideally situated for shipping to world markets. The first jute mill was established at Rishra, on the River Hooghly near Calcutta in 1855 when Mr. George Acland brought jute spinning machinery from Dundee. Four years later, the first power driven weaving factory was set up.

By 1869, five mills were operating with 950 looms. Growth was rapid and, by 1910, 38 companies operating 30,685 looms exported more than a billion yards of cloth and over 450 million bags. Until the middle 1880's, the jute industry was confined almost entirely to Dundee and Calcutta. France, America, and later Germany, Belgium, Italy, Austria, and Russia, among others, turned to jute manufacturing in the latter part of the 19th century.

In the following three decades, the jute industry in India enjoyed even more remarkable expansion, rising to commanding leadership by 1939 with a total of 68,377 looms, concentrated mainly on the River Hooghly near Calcutta. These mills alone have proved able to supply the world demand.

The earliest goods woven of jute in Dundee were coarse bagging

materials. With longer experience, however, finer fabrics called burlap, or hessian as it is known in India, were produced. This superior cloth met a ready sale and, eventually, the Indian Jute Mills began to turn out these

fabrics. The natural advantage these mills enjoyed soon gave Calcutta world

leadership in burlap and bagging materials and the mills in Dundee and other countries turned to specialties, a great variety of which were developed.

|

Jute Mills concentrated on both sides of Hoogly river in 1894 |

|

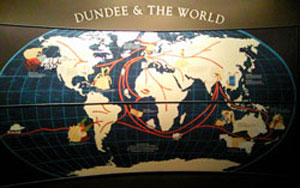

The rise of the jute industry in Dundee

and export of raw jute from the Indian sub-continent.

Dundee & The World - Exhibition London

Jute Industry after 1947

After the fall of British Empire in India during 1947, most of the Jute

Barons started to evacuate India, leaving behind the industrial setup of the Jute

Industry. Most of the jute mills in India were taken over by the Marwaris businessmen.

In East Pakistan after partition in 1947 lacked a Jute Industry but had the finest jute fiber

stock. As the tension started to rise between Pakistan and India, the Pakistani felt the need to setup their own

Jute Industry. Several group of Pakistani families (mainly from West Pakistan)

came into the jute business by setting up several jute mills in Narayanganj of

then East Pakistan, the most significant ones are: Bawanis, Adamjees,

Ispahanis and Dauds. After the liberation of Bangladesh from Pakistan in 1971,

most of the Pakistani owned Jute Mills were taken over by the government of Bangladesh.

Later, to control these Jute mils in Bangladesh, the government built up

Bangladesh Jute Mills Corporation (BJMC). |

|

|

Jute producing countries

The top Ten Jute Producers

are: India, Bangladesh,

People's Republic of China, Côte

d'Ivoire,

Thailand,

Myanmar, Brazil, Uzbekistan,

Nepal,

Vietnam

Jute trade

Jute trade is currently centered around the Indian subcontinent.

Bangladesh is the largest exporter of raw jute, and India is the largest

producer as well as largest consumer of jute products in the world. The

local price of Jute Goods in India is the international price. Nearly 75% of Jute goods are used as packaging materials, burlap

(Hessian), and sacks. Carpet Backing Cloth, the third major Jute outlet, is fast

growing in importance. Currently, it consists of roughly 15% of the world’s Jute goods consumption. The remaining products are carpet yarn, cordage, felts,

padding, twine, ropes, decorative fabrics, and miscellaneous items for

industrial use.

Jute has entered the non-woven industry as it is one of the most

cost effective high tensile vegetable fibre. Therefore, the demand for Jute has

made its way into the automotive industry. Jute is now being used to manufacture

more eco-friendly interiors for cars and automobiles.

Jute Organisatios

The Central

Research Institute for Jute & Allied Fibres (CRIJAF) formerly

known as Jute Agricultural Research Institute (JARI) started

functioning after the partition of India in 1947. The

Gunny Trades Association was established in 1925 in Calcutta (Kolkata)

as a non-profit sharing company. Indian Jute Mills Association (IJMA), Jute Manufactures

Development Council (JMDC), Institute of Jute Technology, Indian

Jute Industries Research Association (IJIRA), Office of Jute

Commission (Ministry of Textile) and many more jute oganisations

after 1947..

The International Jute Study Group (IJSG) is

an intergovernmental body set up under the aegis of UNCTAD to function

as the International Commodity Body (ICB) for Jute, Kenaf and other Allied Fibres.

In Bangladesh, the government built up Bangladesh Jute Mills Corporation

(BJMC), to control their Jute mills. Bangladesh Jute Mills Corporation (BJMC), a public corporation in Bangladesh, is

the largest state owned manufacturing and exporting organization in the world in the jute sector.

See details of the

Jute Organisations |

|

|

Properties of Jute

Jute is one of the strongest natural fibers. The long staple fiber has high

tensile strength and low extensibility. Its luster determines quality; the more

it shines, the better the quality. It also has some heat and fire resistance. Jute is a biodegradable features.

Jute include good insulating and antistatic properties, as well as having low thermal conductivity and a moderate moisture regain.

It include acoustic insulating properties and manufacture with

no skin irritations. Jute has the ability to be blended with other fibres, both synthetic and natural, and accepts cellulosic dye classes such as natural, basic, vat, sulfur, reactive, and pigment dyes.

Jute can also be blended with wool. By treating jute with caustic soda, crimp, softness, pliability, and appearance is improved, aiding in its ability to be spun with wool. Liquid ammonia has a similar effect on jute, as well as the added characteristic of improving flame resistance when treated with

flame proofing agents.

Types of Jute

For general utility purposes, jute products fall into four classes of

manufacture:

HESSIAN or BURLAP: A plain woven fabric of 5 to 12 ozs. a yard,

made of good quality jute yarn. It is used for a wide range of applications

as in cloth form and in the form of bags.

SACKING: It is also known as "heavy goods," made from lower grades of fiber,

loosely woven cloth, in plain or twill weave, weighing from 12-20 ozs. per yard of different widths. It is used for bags of all types.

CANVAS - The finest jute product, closely woven of the best grades of

fiber widely used in India for protection from the weather.

JUTE YARN and TWINE - Most of the single strand jute yarn produced is consumed

by the mills themselves in fabric and twine manufacture. Jute twine in varying

weights and thickness is, used extensively both in India and abroad for

sewing, tying, and for a variety of industrial applications such as packing pipe joints, cable binding, etc.

See the basic products of Jute in detail - Basic Product

Cultivation of Jute

Jute is a rain-fed crop and

its cultivation is concentrated in Bangladesh, India, China, and Thailand. The jute

fibre comes from the stem and ribbon (outer skin) of the jute plant. The fibres

are first extracted by retting. The retting process consists of bundling jute

stems together and immersing them in low, running water. There are two types of

retting: stem and ribbon. After the retting process, stripping begins.

In the stripping process, non-fibrous matter is scraped off, then the workers dig in and grab the fibres from within the jute stem.

See in details Cultivation of Jute

Production of Jute

The production of jute goods from raw jute in jute

mills involves several process. See in details

Production and Manufacturing of Jute Goods

Uses of Jute

Jute is the second most important vegetable fibre after cotton; not only for

cultivation, but also for various uses. Jute is used chiefly to make cloth for

wrapping bales of raw cotton, and to make sacks and coarse cloth. The fibres are

also woven into curtains, chair coverings, carpets, area rugs, hessian cloth, and backing for linoleum.

While jute is being replaced by synthetic materials in many of these uses, some

uses take advantage of jute's biodegradable nature, where synthetics would be

unsuitable. The fibres are used alone or blended with other types of fibres to make twine

and rope. Jute butts, the coarse ends of the plants, are used to make inexpensive cloth. Conversely, very fine threads of jute can be separated out

and made into imitation silk. As jute fibres are also being used to make pulp

and paper, and with increasing concern over forest destruction for the wood pulp

used to make most paper, the importance of jute for this purpose may increase.

Jute has a long history of use in the sackings, carpets, wrapping fabrics

(cotton bale), and construction fabric manufacturing industry. But,

the major breakthrough came when the automobile, pulp and paper, and the

furniture and bedding industries started to use jute and its allied fibres with

their non-woven and composite technology to manufacture nonwovens, technical

textiles, composite production of sheet moulding compound, resin transfer

moulding, vacuum pressing techniques and injection. During 1941, Henry Ford tested the strength of a car trunk made from soybean

fibre and used flax. But after research jute has become the better option over flax in

producing car interiors.

Jute can be used to create a number of fabrics such as Hessian cloth, sacking,

scrim, carpet backing cloth (CBC), and canvas. Hessian, lighter than sacking, is

used for bags, wrappers, wall- coverings, upholstery, and home furnishings.

Sacking, a fabric made of heavy jute fibres, has its use in the name. CBC made

of jute comes in two types, primary CBC and secondary CBC. Jute packaging is used as an eco-friendly substitute.

Jute leaves are consumed as a food in countries. It is a popular

vegetable in West Africa, the Yoruba of Nigeria call it "ewedu" and the Songhay

of Mali call it "fakohoy." It is also a popular dish in the northern provinces of the Philippines, also known as

saluyot. The leaves are rich in betacarotene, iron, calcium, and Vitamin C. The

plant has an antioxidant activity with a significant α-tocopherol equivalent Vitamin E.

Jute diversification

Jute has entered various diversified sectors, where natural fibres are gradually

becoming better substitution. Among these industries are paper, celluloid

products (films), non-woven textiles, composites (pseudo-wood), and

geotextiles. Diversified jute products are becoming more and more valuable to the consumer

today. Among these are espadrilles, floor coverings, home textiles, high performance technical textiles, Geotextiles, composites, and more.

Geotextiles, is more popular in the agricultural sector. It is a lightly woven fabric

made from natural fibres that is used for soil erosion control, seed protection,

weed control, and many other agricultural and landscaping uses. The Geotextiles

can be used more than a year and the bio-degradable jute Geotextile left to rot

on the ground keeps the ground cool and is able to make the land more fertile.

Jute floor coverings consist of woven and tufted and piled carpets.

Jute non-wovens and composites can be used for underlay, linoleum substrate, and more.

Jute has many advantages as a home textile, either replacing cotton or blending

with it. It is a strong, durable, color and light-fast fibre. Its UV protection,

sound and heat insulation, low thermal conduction and anti-static properties

make it a wise choice in home décor. Also, fabrics made of jute fibres are

carbon- dioxide neutral and naturally decomposable. Diversified byproducts which can be cultivated from jute include uses in

cosmetics, medicine, paints, and other products. More details

- Diversification of jute |

|

References

International Jute Study Group (IJSG): Reports on jute, kenaf and roselle plants

Pan, N. C., A. Day, and K. K. Mahalanabis: Indian Textile Journal. Vol. 110

Basu, G., A. K. Sinha, and S. N. Chattopadhyay: Man-Made Textiles in India. Vol. 48

Bangladesh Jute Research Institute (BJRI). The Institute dedicated to jute research.

Institute of Jute Technology, Kolkata: An institute for advanced research on jute and allied fibres.

Royle's: Fibrous Plants of India

Leggatt's: Jute Spinning

Woodhouse and Milne's: Jute and Linen Weaving

The jute industry :Dundee Exhibition,

London

|

|

|